Sponsored By

Latest

thumbnail

Sustainability

What Sustainable Solutions Make Sense for Plastics?

What Sustainable Solutions Make Sense for Plastics?

The tension between engineering and marketing is never more apparent than in sustainable packaging decisions.

NPE News

Next-gen Ultrasonic Welders Have Plastics Fixation

Rinco Ultrasonics aims to show NPE attendees how they can improve efficiency and productivity with next-gen pneumatically driven ultrasonic welding technology.

Apr 17, 2024

|

2 Min Read

Injection MoldingNew Injection Molding Nozzles Improve Gate Quality, Facilitate Maintenance

Apr 16, 2024

|

1 Min Read

Automotive & MobilityNYCOA to Launch Plasticizer-free Long-chain Polyamide Portfolio

Apr 15, 2024

|

3 Min Read

Hot Right Now

Sign up for the PlasticsToday NewsFeed newsletter.

Dispatches from the War on Plastics

What to Expect From Global Plastics Treaty Talks This Month

A mock proposal developed under the auspices of the Swiss government provides a preview of the restrictive policies that may prevail on a global scale.

Apr 14, 2024

|

4 Min Read

Legislation & RegulationsNew EPA Rule Deeply Concerning for Chemicals Industry

Apr 9, 2024

|

3 Min Read

Must Read

An Insider’s Guide to Resin Pricing

Experts share insights on the forces that drive resin pricing and how to navigate the market to ensure you’re getting the best possible deal.

Slideshows

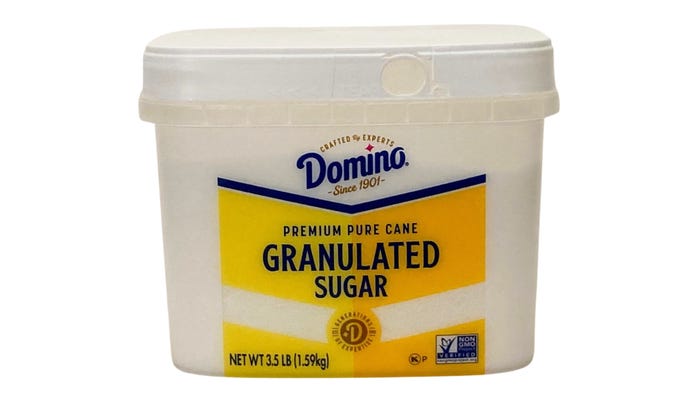

New Domino Sugar Pack Hits Sweet Spot

Rigid plastic packaging for granulated sugar offers numerous ease-of-use and sustainability benefits.

Apr 2, 2024

|

6 Slides

Popular

Discover the latest thinking in injection molding, 3D printing, and new materials, and meet professionals at the heart of design and manufacturing at the Southeast’s largest plastics and polymers trade show. Plastec South is part of IME South, a six-in-one expo offering the latest insights & solutions spanning medtech, packaging, automation, plastics, design, and processing.

Register NowRecent